Magnesium

Magnesium anodes are available in two alloys: a high-potential alloy having a nominal corrosion potential of –1.75 V referenced to a copper-copper sulphate electrode and a low-potential alloy having a nominal corrosion potential of –1.55 V referenced to a copper-copper sulphate electrode. Magnesium is normally used in soils for buried pipelines or in fresh water.

Standard potential alloy – for use in low-resistivity soils and fresh water

High-potential alloy– provides a higher driving voltage than the standard alloy.

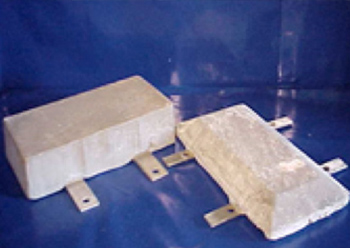

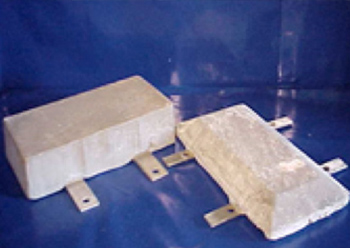

Magnesium anodes used in cathodic protection applications in soil are sometimes supplied pre-packaged with a prepared backfill material in a cloth or cardboard container. The special backfill prevents direct soil contact to reduce localized corrosion of the anode, prevents passivation of the anode caused by reactions with soil salts, provides a low-resistivity environment around the anode, and expands when wet to fill the hole and eliminate air voids. The most common backfill material contains 75% hydrated gypsum, 20% bentonite clay, and 5% sodium sulfate.

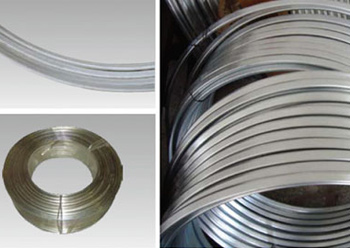

Magnesium ribbon anode

Magnesium anode for fresh water

Bare magnesium anode

Pre-packed magnesium anode

Chemical Composition

| Element | High Potential Magnesium Anode | Standard Potential Magnesium Anode |

|---|---|---|

| Content % | ||

| Aluminium AL | 0.01% max | 5.30 – 6.70% |

| Zinc Zn | – | 2.50% – 3.50% |

| Iron Fe | 0.03 max % | 0.003 max % |

| Copper Cu | 0.02 max % | 0.02 max % |

| Manganes Mn | 0.5 – 1.30 % | 0.15% – 0.70% |

| Lead Pb | 0.01 max% | 0.3 max % |

| Silicon Si | 0.05 max % | 0.10 max % |

| Nickel Ni | 0.001 max % | 0.002 max % |

| Other | 0.05% each 0.3% max total | 0.3% max total |

| Magnesium Mg | Remainder | Remainder |

Electrochemical Properties

| Element | High Potential Magnesium Anode | Standard Potential Magnesium Anode |

|---|---|---|

| Open voltage (-V) | 1.70V to -1.75V | -1.50V to -1.55V |

| Closed voltage (-V) | -1.58V to -1.62V | -1.45V to -1.50V |

| Capacity (A.h/kg) | 1,230 A.h/kg min | 1,230 A.h/kg min |

| Efficiency (%) | 50 % min | 50 % min |

| Consumption rate (kg/A-y) | 7.90 kg/A-y | 7.90 kg/A-y |

All weights in kilograms. All dimensions in millimetres. Lermetal anodes height and width are standard design widely used in the industry market. Our Cathodic Protection Engineer and foundry can customise owner’s and buyer’s requirements upon request.